Industrial automation plays a central role in Oman’s growing manufacturing & infrastructure sectors. Among the various devices that power this transformation, the DVPPS05 DELTA power supply module is a trusted choice for ensuring stable and reliable performance of automation systems. Compact, efficient, and reliable, this module provides the essential DC power required for programmable logic controllers (PLCs) and other equipment. However, the full value of this component can only be realized through proper installation and regular maintenance. In this blog, we will provide a detailed guide for Oman industrial buyers on how to install and maintain the DVPPS05 DELTA. For sourcing genuine components, choosing a dependable Delta automation products supplier in Oman is the first step.

Understanding the DVPPS05 DELTA

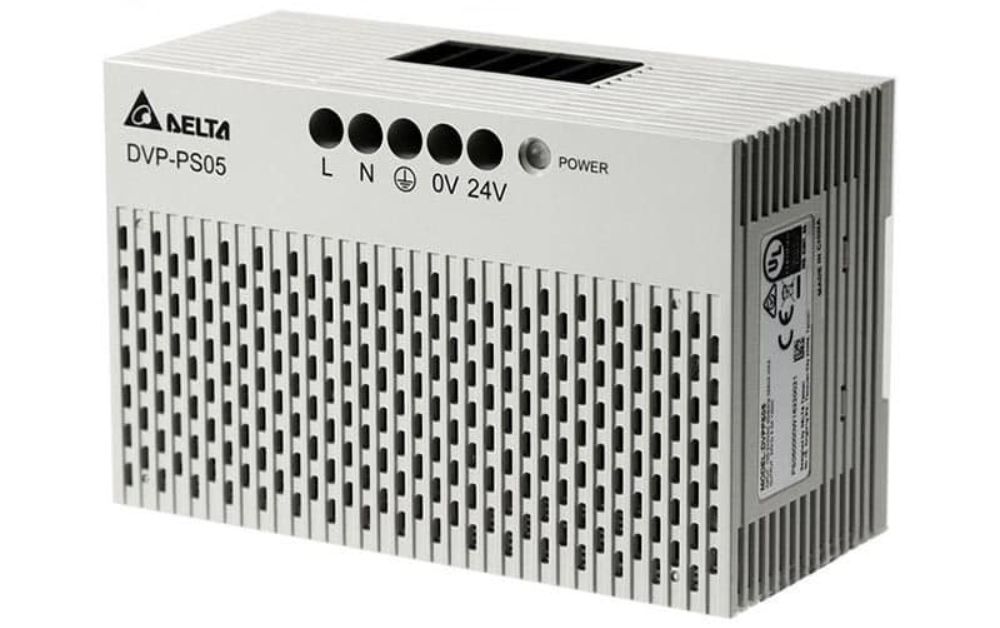

The DVPPS05 is a power supply module designed by Delta for use with its series of programmable logic controllers. It offers:

- Input Voltage: 100–240V AC

- Output Voltage: 24V DC

- Output Current: 2A

- Compact Design: Saves panel space in industrial setups

- Reliability: Stable output with protection against overload and short circuits

This makes it highly suitable for Oman’s industries, which depend on reliable automation equipment in sectors such as oil and gas, manufacturing, logistics, & food processing.

Preparing for Installation

-

Choose the Right Environment

The performance of the DVPPS05 depends heavily on where it is installed. Buyers in Oman should ensure:

- A dry and well-ventilated space, as high humidity & heat can affect performance.

- Installation away from direct sunlight or dust-prone areas.

- Compliance with industrial security standards to decrease errors.

-

Gather Tools and Accessories

Before installation, make sure the following are ready:

- Mounting screws or DIN rail for fixing the module.

- Proper wiring cables with insulation.

- Voltage tester for safety checks.

- Protective equipment for the technician, such as gloves & insulated tools.

-

Check Compatibility

Ensure that the DVPPS05 is compatible with the connected Delta PLC and other devices in the system. Cross-check voltage and current ratings before installation.

Installation Process

Step 1: Mounting the Module

- The DVPPS05 can be mounted on a DIN rail or panel.

- Ensure it is secured tightly to prevent vibrations, mainly in industrial environments like Oman’s oil & gas plants.

Step 2: Connecting the Input Power

- Connect the AC input (100–240V) to the designated terminals.

- Ensure proper grounding for safety & stability.

- Use a circuit breaker upstream to protect the device from unexpected surges.

Step 3: Wiring the Output

- Connect the 24V DC output to the PLC or other connected devices.

- Double-check polarity to avoid equipment damage.

- Ensure wires are properly insulated & secured to prevent accidental disconnection.

Step 4: Testing

- Once connections are complete, power on the unit.

- Use a multimeter to confirm that the output voltage is stable at 24V DC.

- Check for indicator lights (if available) to confirm proper operation.

Maintenance Tips for Oman Industrial Buyers

-

Regular Inspection

Regularly check the DVPPS05 for optimal performance. Look for:

- Loose connections.

- Signs of wear on cables.

- Overheating or unusual noise.

-

Cleaning

The desert conditions in Oman can cause dust buildup. Regular cleaning is a must:

- Remove dirt with compressed air or a soft brush.

- Make sure the headset is powered off before cleaning.

- Do not use any type of cleaning solution that contains moisture.

-

Temperature Control

Oman’s hot temperatures are not friendly to electronics. To manage this:

- Maintain room temperature within the device’s operating range.

- Fit control panels with ventilation or cooling systems.

- The equipment should be kept away from a heat source.

-

Check Load Conditions

Ensure the total current load of connected devices does not exceed 2A.

- Overloading causes overheating & premature failure.

- Use extra modules if the load requirement is higher.

-

Firmware and System Updates

If you have other automation around the DVPPS05:

- Keep the PLC software updated at all times for compatibility.

- While updating, make sure the PSU is stable to prevent data corruption.

-

Professional Servicing

- Additionally, service is provided from time to time by approved technicians.

- If the issue persists, consider consulting a trusted Delta automation products dealer for inspection and replacement next time.

-

Common Mistakes to Avoid

- Reverse Polarity: Connecting the DC output in reverse can cause permanent damage to the PLC or other devices.

- Not Grounded Case: If not grounded, it may cause electric shock & malfunction.

- Overload: If load devices are exceeded, shut down to prevent damage over time.

- Inadequate Ventilation: Failure to provide airflow around the unit will result in overheating.

- Elimination of Routine Inspections: Non-regular checking of these devices may cause an undiscovered malfunction.

Benefits of Proper Installation and Maintenance

When installed & maintained correctly, the DVPPS05 provides:

- Longevity: Extends the lifespan of the module & connected PLCs.

- Cost Savings: Reduces downtime and expensive repairs.

- Energy Efficiency: Provides stable power with minimal energy waste.

- Operational Reliability: Ensures uninterrupted automation processes.

- Safety: Minimizes risks of electrical faults and accidents.

-

Why Oman Buyers Should Prioritize Quality Suppliers

Industrial buyers in Oman face unique challenges such as harsh environments, continuous operations, and growing demands for efficiency. By sourcing genuine equipment from a reputable Delta automation products supplier, businesses can ensure:

- Authentic products backed by warranties.

- Access to technical support & spare parts.

- Reliable after-sales service.

- Compliance with international and local safety standards.

Partnering with the right supplier is just as important as proper installation and maintenance.

In Conclusion

The DVPPS05 DELTA is a compact yet powerful power supply module that plays a key role in supporting automation systems across Oman’s industrial landscape. From oil & gas to manufacturing & logistics, its stable performance ensures smooth operations. By following best practices for installation & maintenance, buyers can decrease its efficiency & longevity. However, success begins with sourcing genuine components from a trusted Delta automation products supplier in Oman.

For businesses looking for dependable solutions & expert support, Apex Global Solutions LLC stands out as a reliable partner for Delta automation products in Oman.